Points of Attention During a Warehouse Inspection

The visual inspection is always carried out from the ground, unless there are indications for a more extensive inspection at full height. This must always be done using a safe access method (lift, scaffolding, ladder, etc.). Climbing on the warehouse racking or uprights is never permitted.

The following items are checked:

- Visual inspection for deformation of the uprights, beams, diagonals, braces, shelves, arms, etc., according to the classification system

- Overloading and uneven loading according to the classification system

- Collision damage

- Vertical alignment of the uprights

- Condition of baseplates and anchors

- Condition of the warehouse floor

- Presence of locking pins in the uprights/beams

- Condition of the collision protection

- Condition of the welds

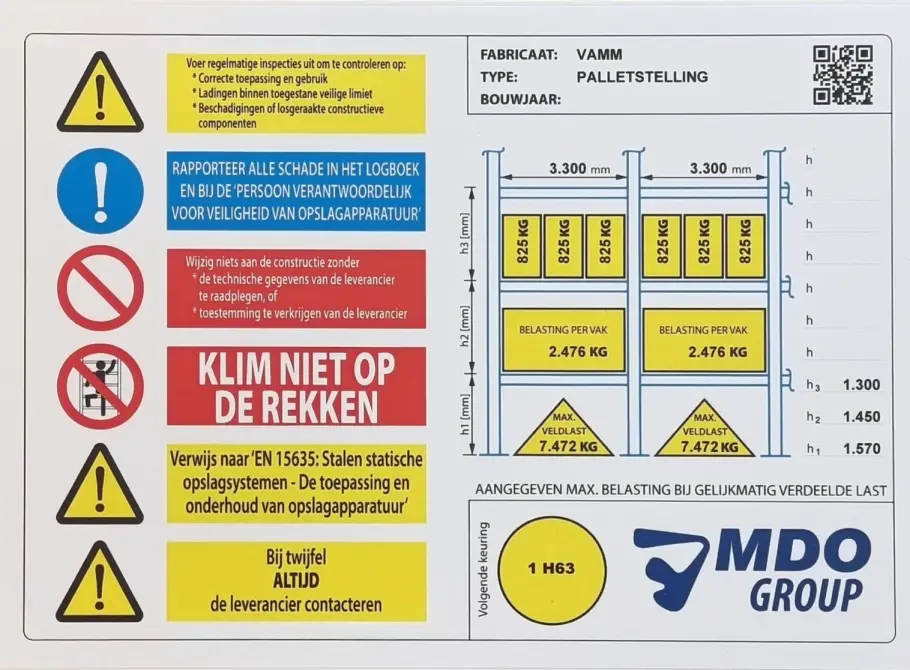

- Presence of a load sign with correct information