To check for structural damage to a stud, a 1 meter level (or stick) can be used, centered in the area of greatest deformation. The distance between the spirit level and the bent part of the post must not exceed 3 mm in the depth direction and no more than 5 mm in the longitudinal direction. If the stile is damaged in both width and length, these must be measured separately. Connections of beams and uprights must not be visibly deformed to such an extent that a danger to the user could arise. Weld seams between the carrier profile and the connecting parts must not contain any cracks.

A green code is assigned to undamaged racks and damaged racks that do not exceed the following limits:

- < 3 mm in depth direction

- < 5 mm in longitudinal direction

- < 10 mm arc diagonal

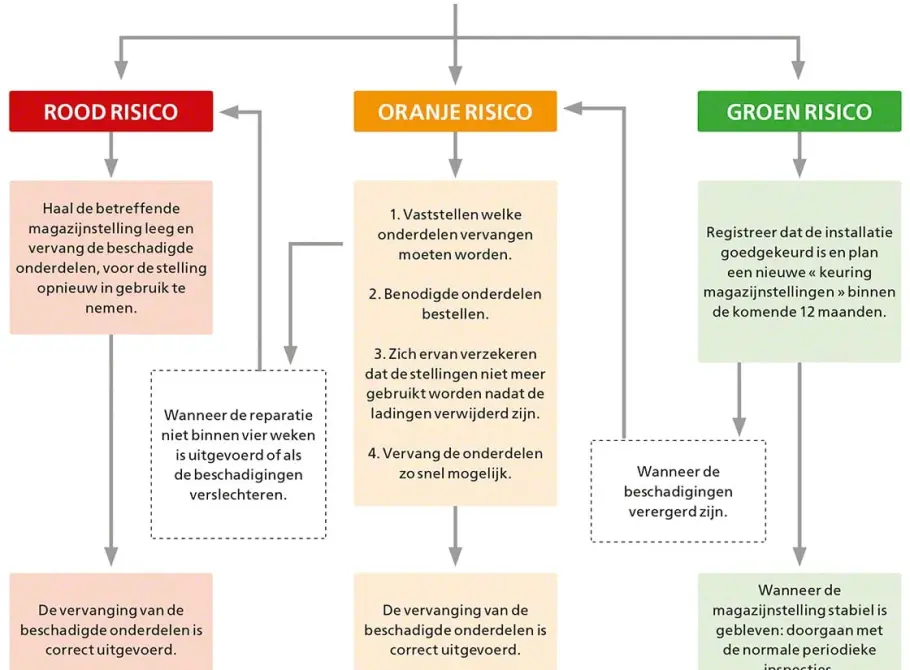

In these cases the damage represents a relatively low risk and the rack is suitable for further use until the next inspection. If the severity of the damage has not increased at the next inspection, the rack can continue to be used. If the severity of the damage has increased, an orange code is assigned according to the standards below.

- 3 to 6 mm in depth direction

- 6 to 10 mm in longitudinal direction

- 10 to 20mm arc diagonal

In this case, the user is advised to order the replacement parts and carry out the repair as soon as possible. If this does not happen within 4 weeks, a red code will be assigned. A red code is also assigned to racks that exceed the tolerances below.

- 6mm in depth direction

- 10mm longitudinal

- 20mm arc diagonal

This is a critical condition where the damaged section must be cleared immediately: remove the load and demarcate the section with a barrier tape (red-white). Necessary repairs must be carried out immediately. When the repairs have been carried out correctly, the rack may be put back into service.