- You are here:

- Home

- Rack projects

- 3D laser scanning for custom platform

3D laser scanning for custom platform

Precision and Efficiency Thanks to 3D Laser Scanning for Custom Platforms

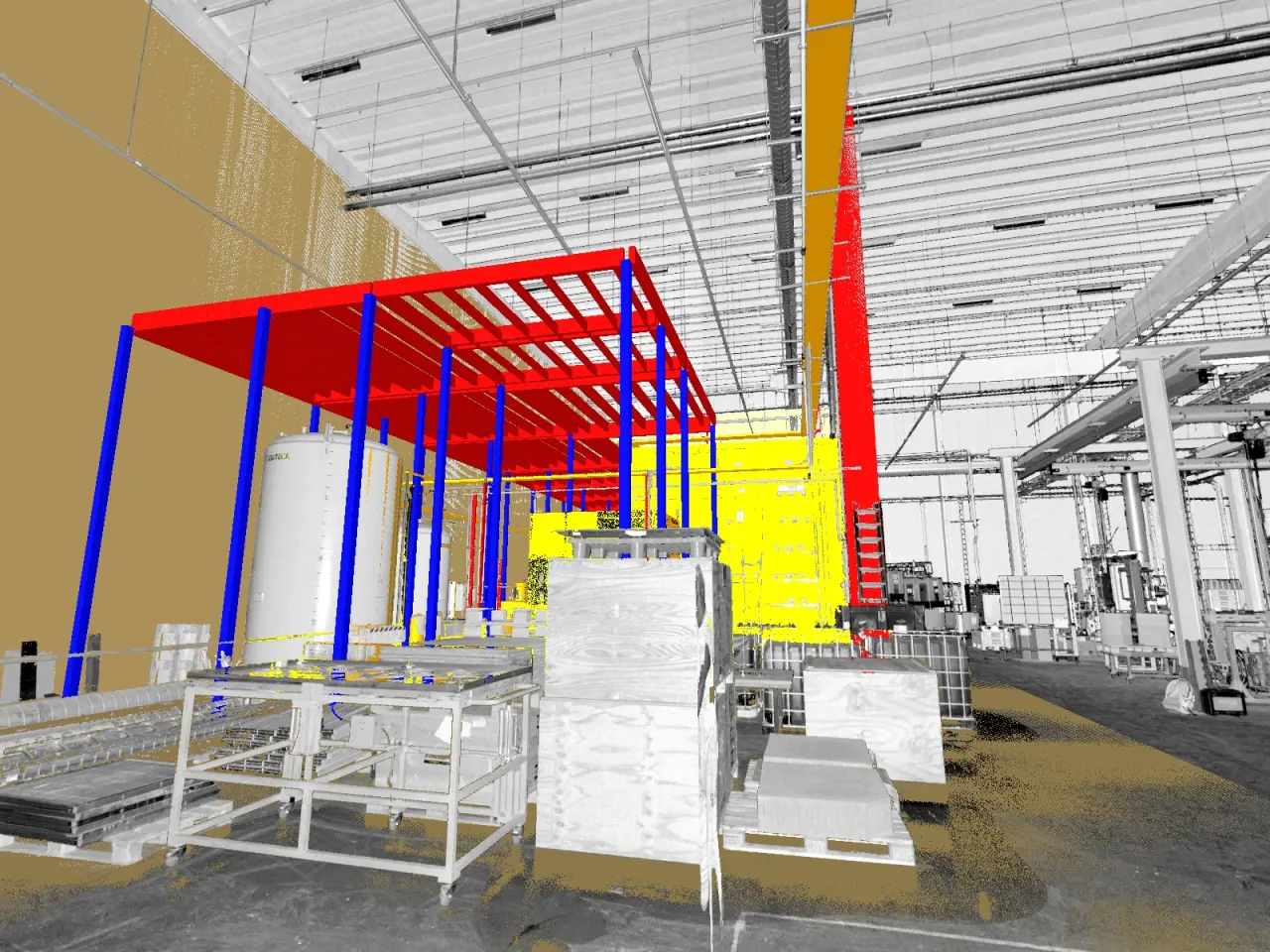

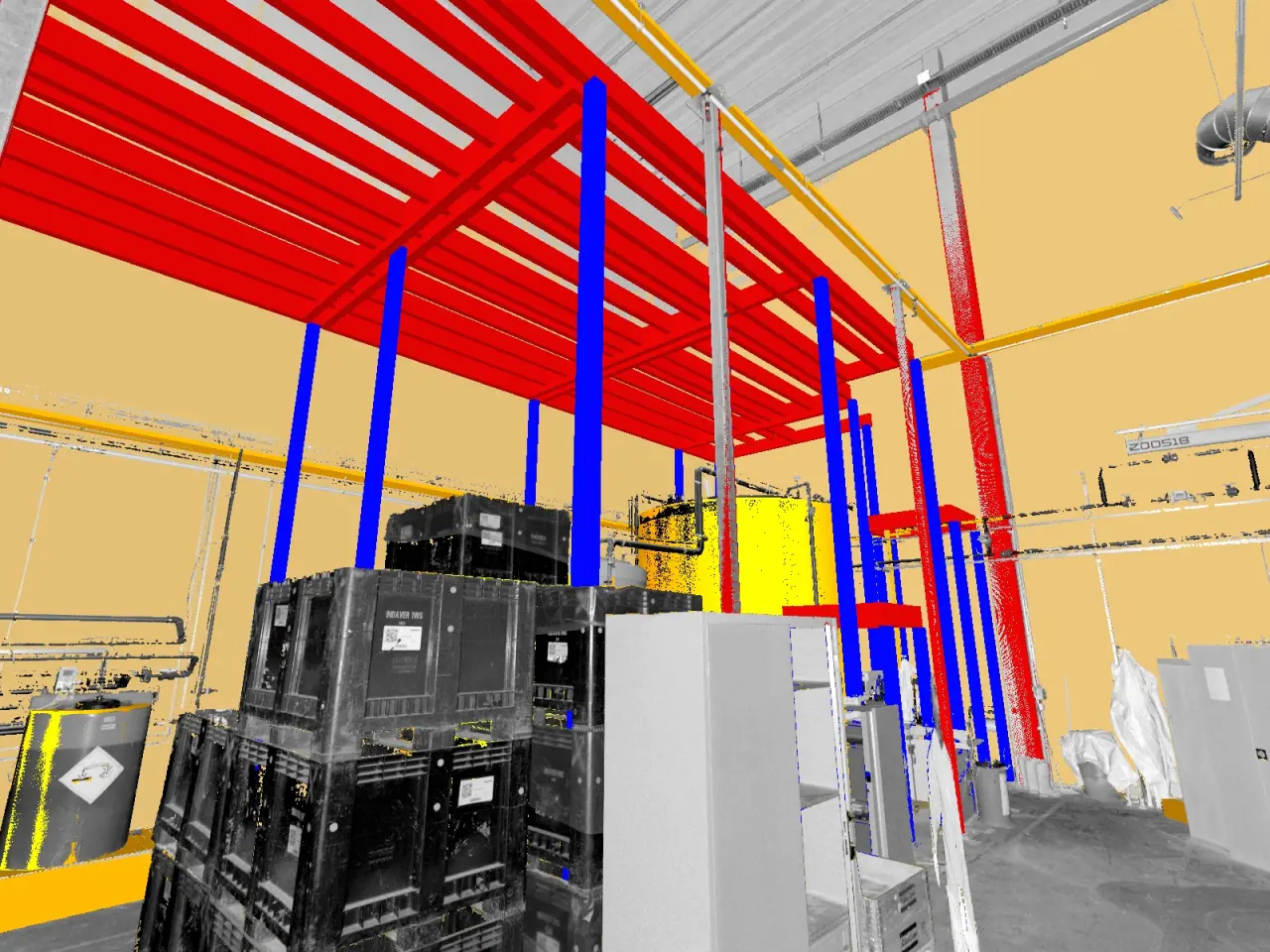

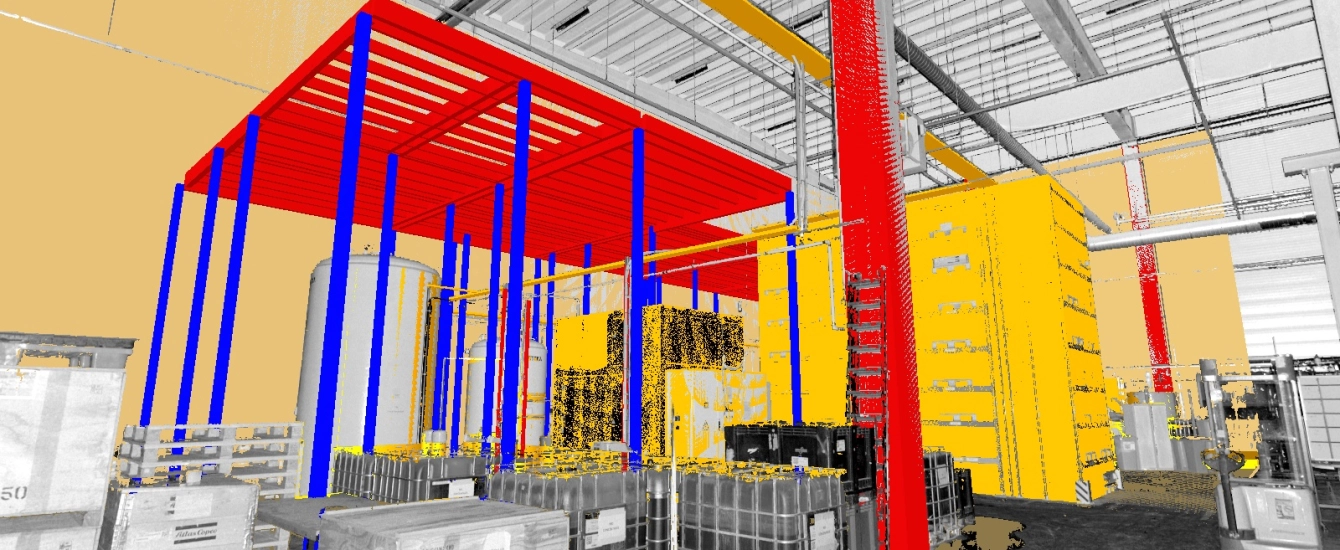

For an industrial client, MDO Group installed a tailor-made steel platform in an existing company facility. To ensure smooth integration, the building was first measured using a 3D laser scanner. This technology allows us to create a digital twin of the environment, enabling highly accurate planning and design.

By using 3D laser scanning, all potential conflicts and clashes are identified and resolved during the design phase. This prevents surprises during installation and guarantees a quick and flawless assembly of the platform.

Based on the digital measurement, we designed an efficient, customized steel structure fully adapted to the client’s existing infrastructure. The result is a safe and space-saving solution, perfectly integrated into the existing production process.

Benefits of This 3D-Optimised Platform Installation

- 3D laser scanning for accurate measurements and planning

- Early detection and resolution of conflicts in the design phase

- Quick and error-free installation with no on-site surprises

- Custom-made steel structure tailored to the existing building

- Optimal use of vertical space in warehouse or production environments